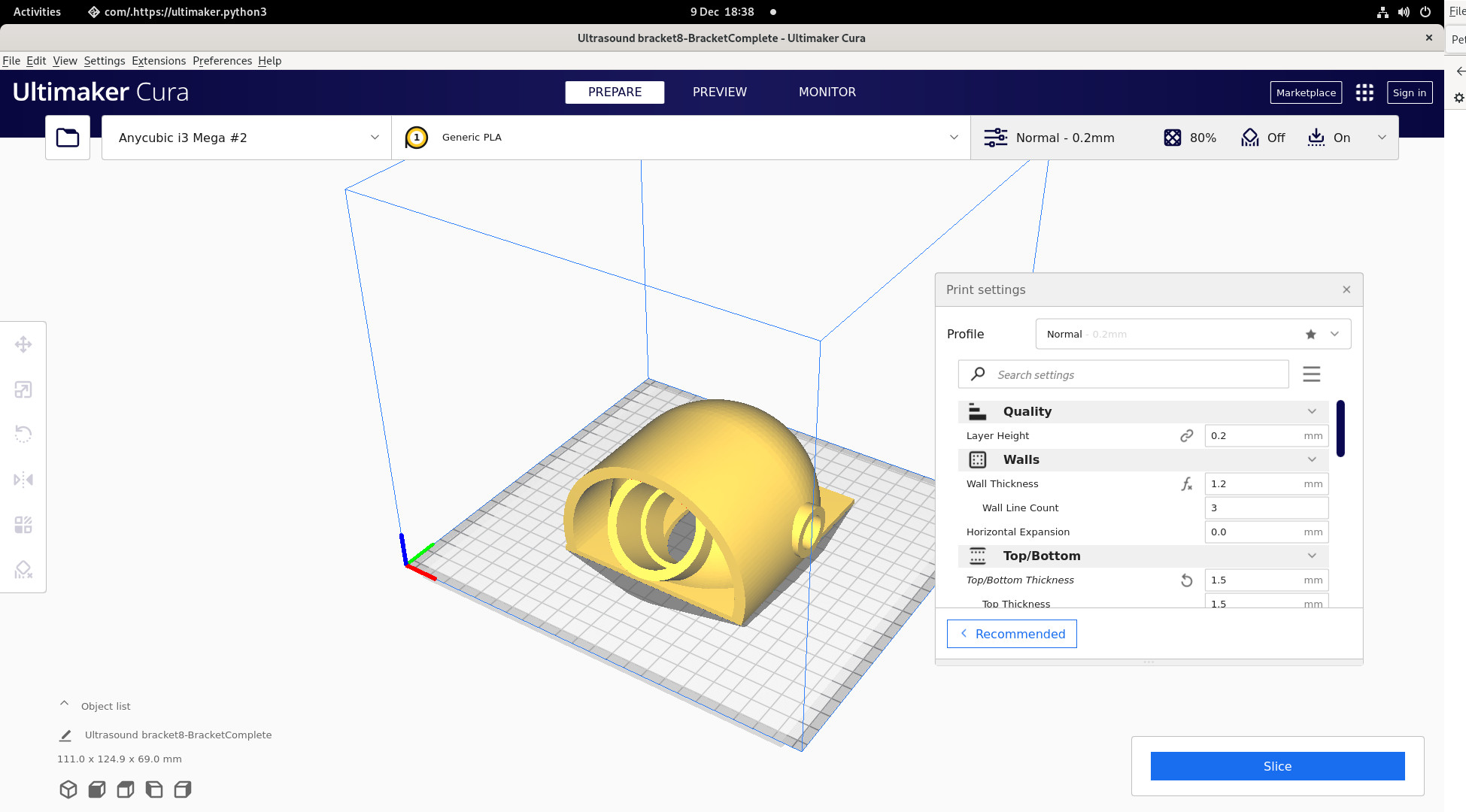

Anycubic

|

It must be said that 3-D printing is hardly a low-cost production environment, but in recent years companies have set up

production units with multiple printers to produce small-ish quantities with very much lower setup costs than the more

established injection moulding method. 3-D printing is also more suitable for designs with complex voids, which would otherwise have to be

assembled from several parts.The range of materials available for 3-D printing is surprising, and even some suspension and engine

parts are made of titanium for formula 1 cars.

Some years ago I started with a very basic build-it-yourself machine made of perspex and MDF. It was surprisingly robust for it's simplicity, and the machines that

work straight from the box were rare - the Reprap community were the developers and required support. I tried it

out of curiosity, and had to download the Arduino software (and the software loader) from the Reprap community.

But it was too much of a fiddle for regular use so it had to be replaced.

The supply picture changed dramatically over a few years, with several companies marketing cheap and easy-to-use machines. So in 2019 I decided not to build a better one for myself,

and got the Anycubic. This worked straight from the box like all the standard printers available now, and it gives very reliable service

over a build plate about 200mm square.

It doesn't have fancy things like automatic bed levelling, but I find I can get on perfectly well

without it. It also runs stand-alone from memory cards loaded with GCode files.

|

Ultimaker Cura

|

This application software has been developed by a company that designs and markets 3-D printers, but it publishes

the application free. It can be set up to work with with many brands of 3-D printers, and I run it on my Fedora linux computer.

There are alternative programs (such as slic3r) but this is very popular and seems to work very well for the sort of things I do.

It takes in a STL file (such as prepared with FreeCAD, or downloaded from a developer) and converts it into a GCode file that

can be used by 3-D printers and other production equipment. When using Cura the characteristics of the intended printer, and the type of

material being printed (e.g. PLA, ABS, nylon, even chocolate) must be specified, and a suitable file is prepared for the printer to use.

This process only needs to be done once to print many identical copies, but needs to be repeated with different settings for different printers.

The component being printed can be rotated, scaled or duplicated as required from the original STL file.

|

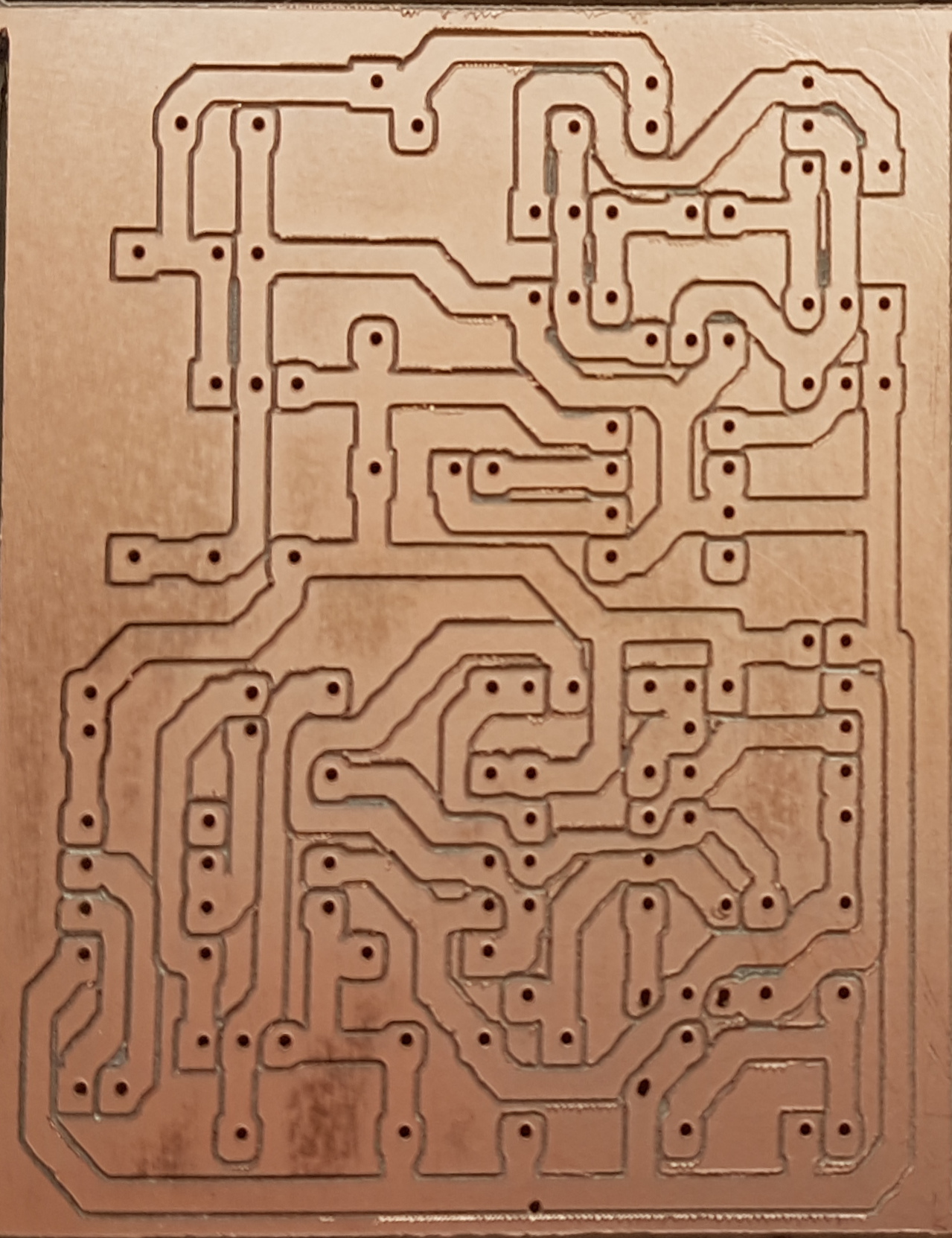

PCB Engraver

Sample PCB

|

For many years I was obliged to build my circuit boards from padboard, and hand-stitch all the wiring.

While I learned to make a neat and robust job I found it time consuming and generally tiresome, so I decided to

make proper PCBs. But I had problems with the conventional photo-chemical processes, notably that I couldn't prepare

a dense enough photographic transparency to give reliable exposure. It also left me with the problem of drilling many holes

with sufficient accuracy, which also promised to be tiresome and slow with my drill-press mounted Dremel and mini-workbench.

So I decided to use an engraver that could be controlled with GCode files in the same way as a 3-D printer. Software is available

to convert the Gerber format files produced by the PCB editor (see above) for the tracking and the drilling.

But when I did some mesurements and calculations

it promised to be prohibitively expensive - at least 4 figures Sterling for a commercial unit.

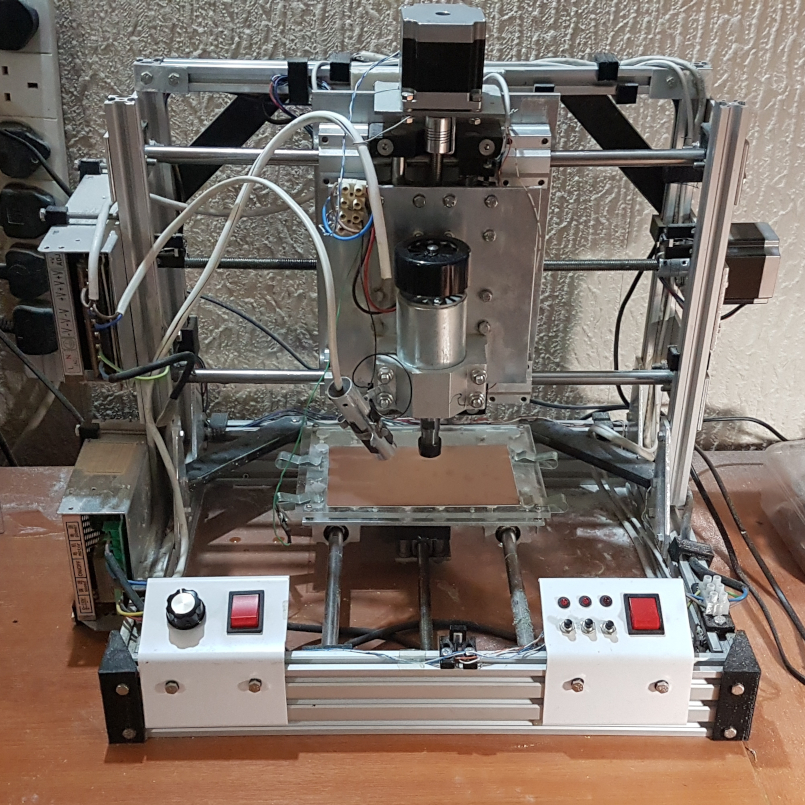

The requirement is very different from a 3-D printer, which are inexpensive and may look similar in structure:

* When printing, there is no lateral force on the print head as it is only laying down a string of melted plastic. An engraver has substantial lateral forces.

* It needs to be much more accurate. I set a tolerance limit of 5 microns (compare with 50-100 microns for 3-D printing).

* It needs a strong motor to ensure consistent engraving, which is much heavier than a print head.

Taking these things and others into account it became clear that I couldn't buy an engraver or adapt a printer, and had to design and build my own, as pictured.

The overall cost was about £300, and I avoided the high cost of Acme screw units with 8mm threaded rods. But these did not come with

standard anti-backlash followers, so I had to design those to suit the loads expected.

As can be seen in the picture, the construction is from simple 5mm aluminium plate and extrusions using captive nuts. The stepper motors

are rather larger than usually found in printers, and the guide rods are much stronger (12mm stainless, compared with 8mm).

Having limited workshop facilities I made some critical components with the old 3-D printer, as seen in black, these include corner braces,

guide rod support blocks, power unit clamps and cable clips.

The only serious problem was overcoming the natural curvature of the PCB blanks. When engraving with a cone-shaped cutter the slightest variation in

depth (Z axis) results in substantial variation in cut width. A Z-axis consistency of better than 0.05mm is essential, but even with various clamps

this could not be achieved.

I used a standard CNC card to control the machine, but it did not have bed-levelling capability. Eventually I overcame this problem by preparing a bed-levelling

routine which applies geometric corrections to the source files.

The results are now very good. From the files prepared by the PCB editor the machine engraves, drills and cuts out from the blank, all precisely registered, when fitted with the appropriate tools.

|